The difference between 4 types of UV stabilizers for plastic products

The difference between 4 types of UV stabilizers for plastic products

In order to avoid the aging and oxidation problems of plastic products and resist the damaging effect of ultraviolet rays, it is necessary to add ultraviolet stabilizers and antioxidants to the ingredients.

As we all know, the ultraviolet component in natural light has the strongest destructive power to plastic products because it contains the strongest energy.

Through continuous experiments, we explore anti-ultraviolet rays and delay the aging speed of plastic products, thereby improving the service life of plastic products.

UV stabilizers added to plastic products can inhibit the damaging effects of UV rays. By absorbing or converting ultraviolet rays, it can block the damage of ultraviolet rays to chemical links in polymer materials.

What are the types of UV stabilizers?

There are 4 types of UV stabilizers, hindered amine light stabilizers, UV absorbers, quenchers and UV shielding agents.

So what are their differences and advantages?

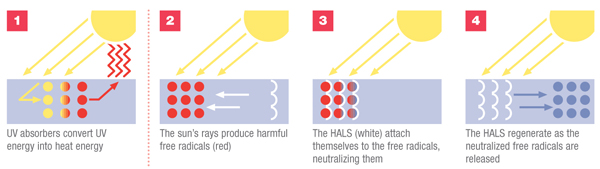

- Hindered amine light stabilizer is the most widely used UV inhibitor, also known as HALS. Because of its low cost, good effect and long effective time, it is widely used. Its usage accounts for about 60% of the total. The principle of action of HALS is to terminate the oxidation reaction by inhibiting free oxygen ions. This ingredient removes free radicals and quenches oxygen ions through photo-oxidation by establishing a Denisov cycle. This long-acting stabilizer can very effectively inhibit the damaging effect of ultraviolet rays. HALS light stabilizers have long-term effects, good effects, and little effect on color. So very popular.

- Ultraviolet absorbers, by absorbing ultraviolet rays, converts them into infrared rays, thereby reducing the damaging effects of ultraviolet rays. The main components of UV absorbers include benzophenones, benzotriazoles, and salicylates. The most commonly used UV absorber is UV326. These UV absorbers are also oxidized, so their use time is not as long as that of light stabilizers, but because of lower cost and low manufacturing process requirements, they are also widely used, accounting for about 25% of the market.

- The quencher eliminates free excited electrons through energy transfer between molecules, thereby converting chemical energy into thermal energy. The application of quenchers in industrial products is mainly concentrated in agricultural film materials. Because this quencher is most effective in adhering to the surface of plastic products, its application is greatly limited. And because of technical problems such as wear resistance and discoloration, it has been eliminated and replaced in some areas.

- UV shielding agent, including carbon black masterbatch, titanium dioxide and zinc oxide. They can block UV rays, reflect or absorb UV rays, thus acting as UV shields. Carbon black is one of the most effective and commonly used UV stabilizers. Because carbon black masterbatch can act as a shielding agent as well as a coloring agent, it is widely used. However, it is generally not used alone as a UV stabilizer. It is usually used in combination with other ingredients to achieve a more efficient UV stabilizer effect.

Main manufacturers of UV stabilizers: BASF, Clariant, Cytec, Eastman; Asahi Kasei, etc.

Conclusion

By considering a variety of conditions, the appropriate UV stabilizer is selected to enhance the performance and product quality of plastic products. This is a very important research and application.

We have very rich production experience, and also have a large number of testing and experimental equipment to ensure that our production process and composition ratio can meet customer requirements. This is also a rigid requirement of our strict quality management system.

If you are interested in our products, welcome to consult for instant quotation.